Optimizing S&OP (3):

Making relevant information available to all supply chain stakeholders brings transparency and therefore clarity to any process, but this is especially valid and indeed crucial in forecasting and planning. Companies often plan exclusively in volumes without translating forecasts into value. And managers are often confronted – not to mention confused – by differences between the forecasts of sales people, the estimates (for the future) of logistics people, and the annual forecasts of the finance department.

The S&OP process needs to move away from the operational process into an integrated business process involving finance and using scenario planning instead of volume-based decisions. The benefits of ‘value-based S&OP’ and ‘one-number planning’ need to be made equally clear to all stakeholders. Although supply chain management will be familiar with these, the benefits are not always clear to sales & marketing. However, it must be remembered that the objective is consistent planning. Sales must reflect optimism and the forecasting process should not become a purely mathematical exercise devoid of enthusiasm.

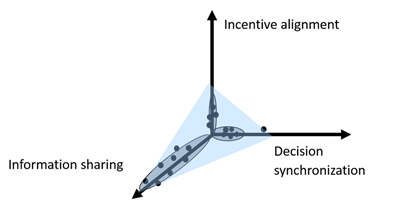

Sharing of information is not limited to the internal organization. Also exchange of relevant information and collaboration with partners outside the company (customers, suppliers) contributes to improved planning accuracy and stability. The level of collaboration within a company on forecasting and planning can be determined using a ‘collaboration index’ (Simatupang, Sridharan 2005), which measures three important dimensions:

- Information sharing among supply chain partners.

- Decision synchronization among supply chain partners.

- Incentive alignment among supply chain partners.

Figure 1: Collaboration index for forecasting and planning.

Combining the collaboration index with the basic forms of collaboration shows the impact of intensified collaboration.

Figure 2: Combined form and index.

Research shows that data sharing between partner companies happens quite a lot, although differences arise in the way it is shared (Van Geel, 2007). The main problem seems to be in finding time (or being disciplined enough) to discuss it, which is the crucial factor in turning data into value-added information. However, it is common to share product information (portfolios and life cycles) unless this is withheld for strategic reasons. The question remains, to what extent can data that is being shared be interpreted and transformed into valuable information to make supply chain decisions?

Decision synchronization, or the level at which supply chain partners mutually decide on important aspects of their forecasting and planning relationship, usually touches areas such as production start-up quantities and timing, ordered-material quantities and timing, priority settings and allocation of capacity alignment. In reality, meetings among supply chain partners are more likely to cover burning issues and how to resolve operational hiccups. Despite general awareness among partners of the benefits that forecasting and planning might bring for end- to-end visibility, there are still reservations about whether it will really work and what pitfalls await.

Third article in a series about sales and operations planning (S&OP)

Today, S&OP is considered as being the key means to execute corporate strategy. A successful S&OP process aligns an organization strategically to execute tactically. The implementation of the S&OP process requires changes to processes, organizations and systems.13 building blocks are identified that compresses the path for companies towards achieving game-changing benefits by following a step-by-step approach to S&OP success.

Read about the first step: Set clear planning objectives and make timely decisions.

Read about the second step: Make S&OP a regular process with predefined steps

Optimizing your S&OP?

TIAS offers the Executive Master of Operations and Supply Chain Excellence which is a 11-module program, completed over a 22-month period. It offers you the latest theories, techniques and skills needed to successfully define and execute your company’s operations strategy.

Read more about the MOS program